NEBS (Network Equipment Building Systems)

If your receiver installation needs to follow the NEBS requirements and guidelines, please follow these guidelines to be NEBS compliant.

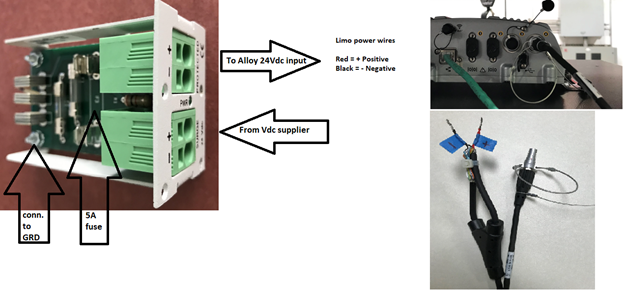

DC power supply surge protection

The Alloy lemo cable must be connected to a Transtector V DC power surge protector. Trimble recommends that in-line lightning arrestors are mounted on a low impedance ground at the point where the cable enters the building. The NEBS compliance is based on the following Transtector V DC power surge protector (P/N1000-1464) at www.transtector.com/dc-surge-protector-spd-cpx-indoor-module-1000-1464. See the following drawing for more information.

NOTE – The Alloy receiver can operate from +9.5 V DC to +28.0 V DC at a maximum current level of 4.7 A, the DC input is reverse polarity protected. Reversing polarity with 24 V DC options does not cause damage to the device.

NOTE – The power cable should be routed separately from the data (signal) cables.

The intra-building ports of the equipment or sub-assembly are suitable for connection to intra-building or unexposed wiring or cabling-only of the intra-building port(s) of the equipment or sub-assembly. The intra-building ports must not be metallically connected to interfaces that connect to the OSP or its wiring. These interfaces are designed for use as intra-building interfaces only (Type 4 or 4a ports as described in GR-1089: Electromagnetic Compatibility and Electrical Safety) and require isolation from the exposed OSP cabling with the addition of primary protectors.

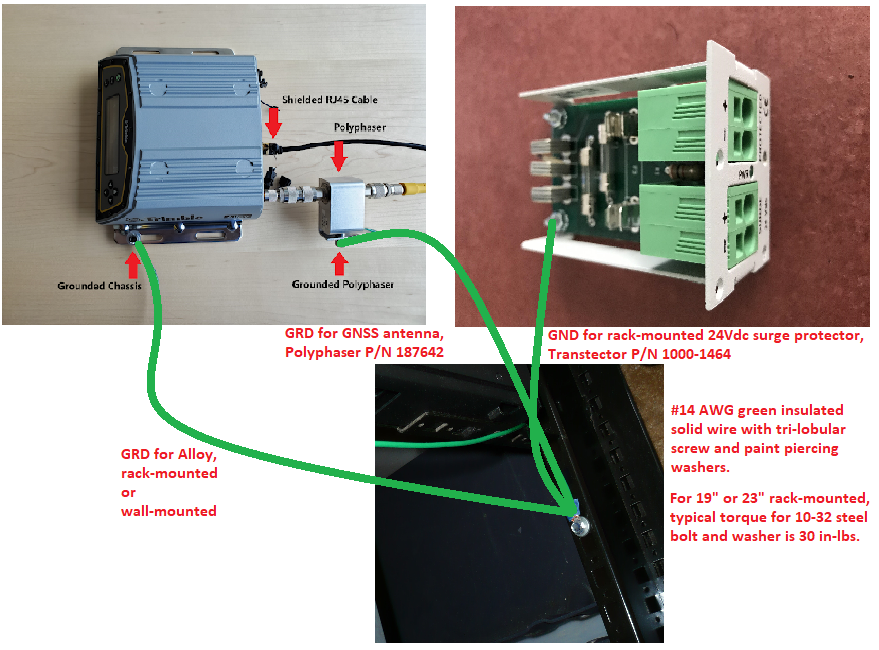

Grounding the Alloy receiver for NEBS compliance

The receiver must be grounded via a copper ground conductor, and the device must be installed and connected to the common bonding network (CBN). The receiver DC power returns need to be treated as DC-I (Isolated from Frame Ground). The receiver is suitable for connection to the CO and CPE. For security reasons, the receiver must be located in a restricted access location where only trained service personnel can access.

Before connections are made, all bare grounding connection points to the receiver must be cleaned and coated with an anti-oxidant solution. Trimble recommends the surfaces on the receiver that are unplated should be brought to a bright finish and treated with an anti-oxidant solution before a connection is made with the antenna cable, lemo cable, RJ45 cable, and any other required connections.

All non-conductive surfaces on the receiver will be removed from all threads and connection points to ensure electrical continuity. The GNSS antenna cable and RJ45 cable need to be inspected for breaks in the outer shield before installation.

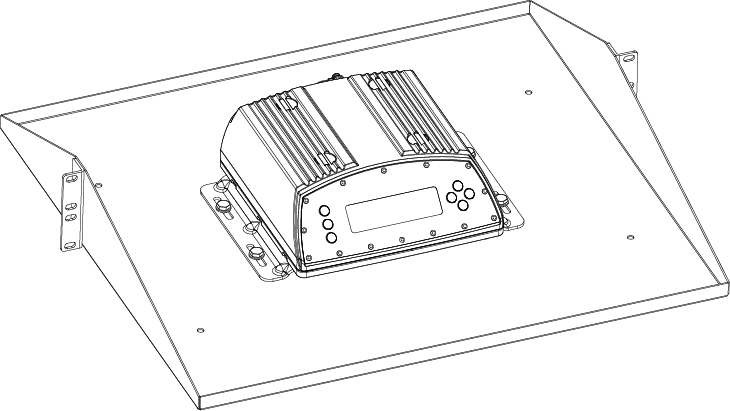

Mounting the Alloy receiver to a rack for NEBS compliance

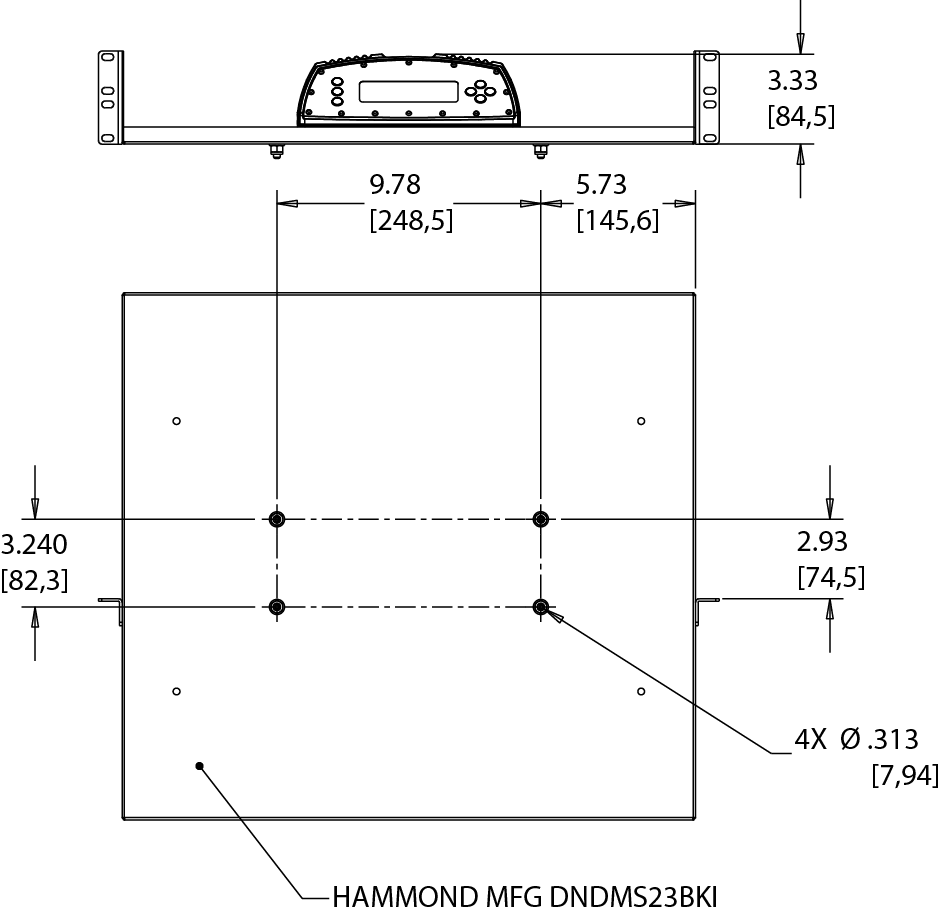

Trimble recommends that the receiver is either wall-mounted or rack-mounted to decrease the chances of the receiver being harmed or out of commission during an earthquake or other disaster. Trimble recommends that the receiver is installed in an environmentally-controlled cabinet with an EIA standard 19-inch or 23-inch mounting rack, for example, www.rackmountsolutions.net/hammond-dndms23bk1-23-2u-centered-2-post-rack-shelf/.

23 inch rack mount:

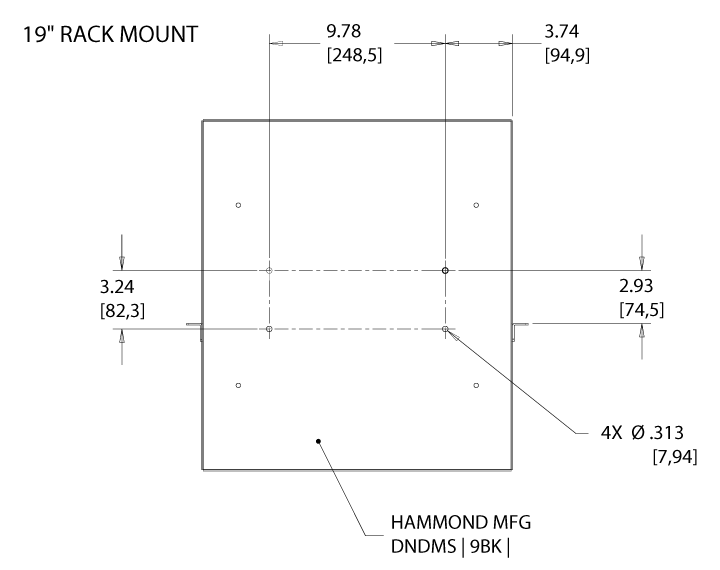

19 inch rack mount:

Hardware for both rack mounts:

|

Hardware |

Quantity |

|---|---|

|

1/2-20 × .75 or M6 × 18 hex head bolt stainless steel (A2) |

4 |

|

1/4 or M6 flat washer stainless steel (A2) |

8 |

|

1/4-20 or M6 nylon insert locking nut stainless steel (A2) |

4 |

NOTE – Keep one rack-unit of space (1.75 in) empty above the device, which allows a small amount of convectional airflow. Forced airflow is not required.